HVAC & Industrial Automation

Shivoham HVAC & Industrial Automation Solutions deliver smart monitoring, control, and inspection technologies to optimize factory performance, reduce energy consumption, and enhance equipment reliability. The solution combines thermography-based inspection, automated control systems, and pneumatic/electric actuation technologies to enable real-time supervision of machines, utilities, and HVAC infrastructure ensuring safe, efficient, and uninterrupted operations across industrial facilities.

Key Principles and Technology

Industrial Machine Inspection via Thermography

Advanced thermal imaging for non-invasive hotspot detection and early fault identification.

Automated HVAC & Utility Monitoring

Continuous monitoring of chillers, compressors, pumps, air handling units, and ventilation systems.

Pneumatic & Electric Actuation Systems

Integration of actuators, filters, regulators, valves, and flow control devices for precise automation.

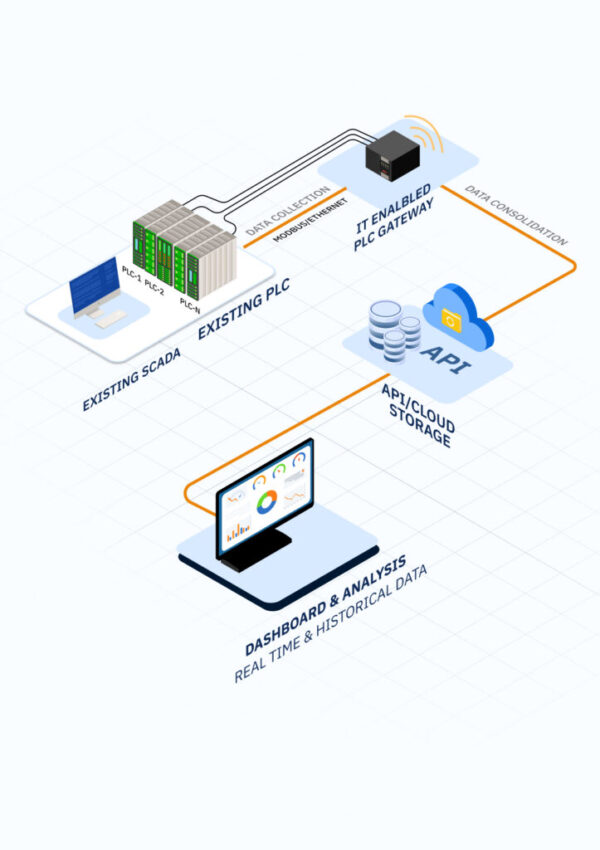

Centralized Control & SCADA Integration

Real-time visibility and control through centralized dashboards and automation platforms.

Pressure & Flow Optimization

Intelligent control of compressed air and fluid systems to minimize energy loss.

Scalable Industrial Architecture

Supports small production lines to large multi-plant facilities.

Benefits & Implementation

Benefits

- Energy Saving & Efficiency Improvement

- Early Fault Detection

- Comprehensive Automation Systems

- Reduced Downtime & Maintenance Costs

- Improved Process Reliability

- High Flexibility Across Industries

Implementation

- System Assessment & Energy Audit

- Sensor & Controller Deployment

- Pneumatic & Electric Automation Setup

- Centralized Monitoring Dashboard