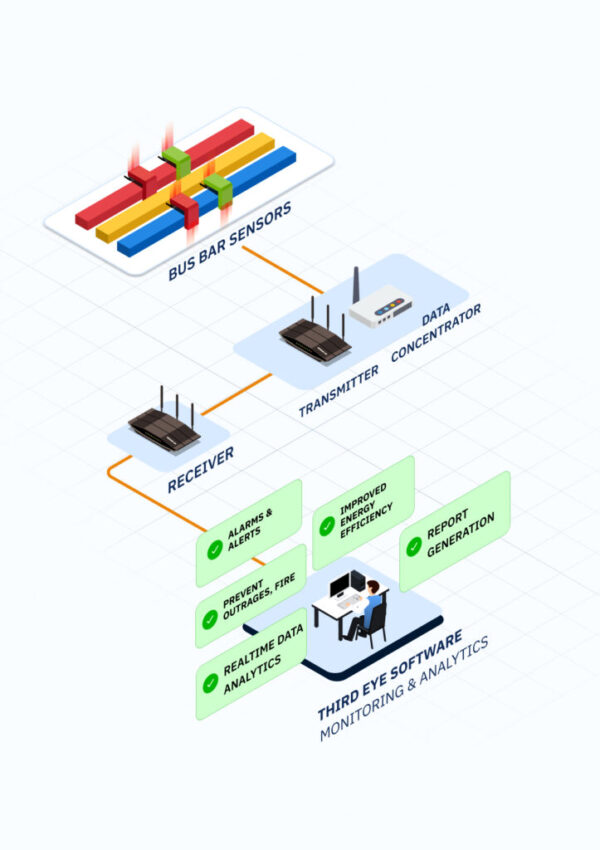

Bus Bar Temperature Monitoring

Our Bus Bar Temperature Monitoring System uses automated thermography to continuously detect hotspots in substations and electrical panels. The solution enables non-contact, real-time thermal monitoring of bus bars and critical connections, eliminating the need for staff to open live panels significantly improving safety while ensuring reliable operation.

Key Principles and Technology

Automated Thermography-Based Monitoring

Uses infrared thermal imaging to continuously measure bus bar and connection temperatures.

Non-Contact & Non-Invasive Detection

No physical contact or sensors attached to live conductors, ensuring safe monitoring.

Continuous Real-Time Surveillance

24×7 automated monitoring of substation panels and switchgear compartments.

High-Resolution Thermal Imaging

Detects minor temperature variations to identify developing hotspots early.

Multi-Point Coverage

A single camera or sensor can monitor multiple bus bars and panel sections simultaneously.

SCADA & System Integration Ready

Easily integrates with SCADA, alarms, and asset management platforms.

Benefits & Implementation

Benefits

- Enhanced Personnel Safety

- Early Hotspot Detection

- Prevention of Breakdowns & Fire Risks

- Reduced Manual Inspections

- Improved Reliability & Uptime

- Lower Maintenance & Operational Costs

Implementation

- Thermal Camera/Sensor Installation

- Strategic Coverage Planning

- Continuous Data Acquisition

- Alarm Threshold Configuration

- Remote Monitoring & Dashboards