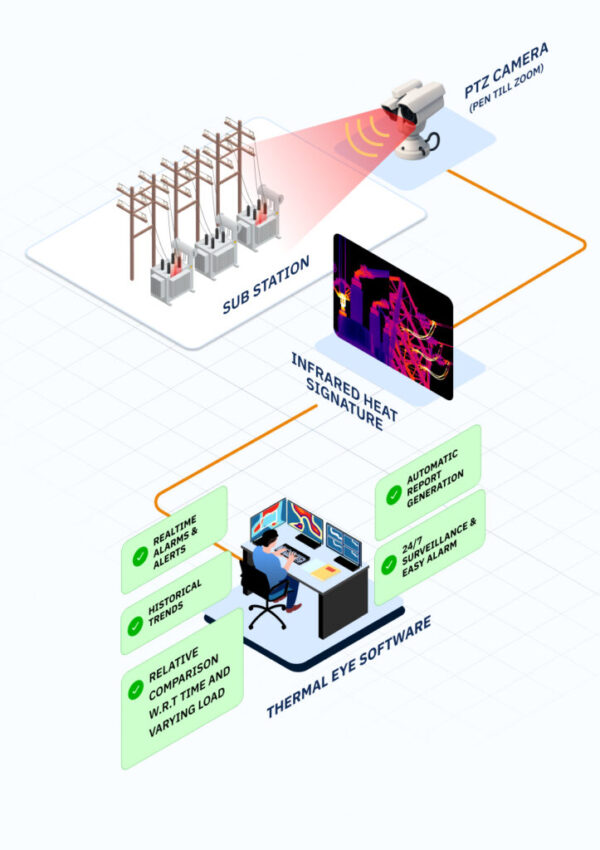

Real-Time Thermal Imaging System

Shivoham’s Automated Thermal Monitoring solution integrates Pan-Tilt positioned with advanced Infrared (IR) and visual cameras for continuous, non-invasive condition monitoring of critical assets.

Key Principles and Technology

Automated Pan-Tilt Thermal Camera System

Uses automated Pan-Tilt Infrared and visual cameras with horizontal and vertical rotation to capture thermal radiation and radiometric data.

Non-Invasive Condition Monitoring

No physical connection to assets is required, enabling safe hotspot monitoring during live operation.

Wide Area Coverage

A single camera can monitor multiple assets and numerous measurement points effectively.

Real-Time & Remote Monitoring

Enables live thermal image viewing from the control room or remote locations.

Wireless Communication Architecture

Thermal and visual data is transmitted wirelessly from cameras to the control room.

System Integration Capability

Seamlessly integrates with SCADA, existing asset management systems, and third-eye software.

Benefits & Implementation

Benefits

- Early Hotspot Detection

- Prevention of Failures & Fire Hazards

- Revenue & Downtime Reduction

- Temperature Trending & Comparison

- Operational Efficiency Improvement

- Enhanced Asset Reliability & Safety

Implementation

- Strategic Camera Placement

- Long-Distance Deployment

- Wireless Data Transmission Setup

- Real-Time Monitoring & Alarm Configuration

- Integration with Control Systems

- 24×7 Automated Operation

PTZ Thermal Camera Highlights

- Dual Camera System – Thermal + Visual Cameras

- Industrial-Grade Enclosure – IP66 with Pan & Tilt mechanism

- Wide Operating Temperature Range – -40°C to +65°C

- Substation-Ready Models Available – IEC 61850-3 & IEEE 1613 compliant

- Long-Range Installation Capability – Ideal for large substations and yards

- Wireless Communication – Reliable data transfer via radio modems