Wind Farms

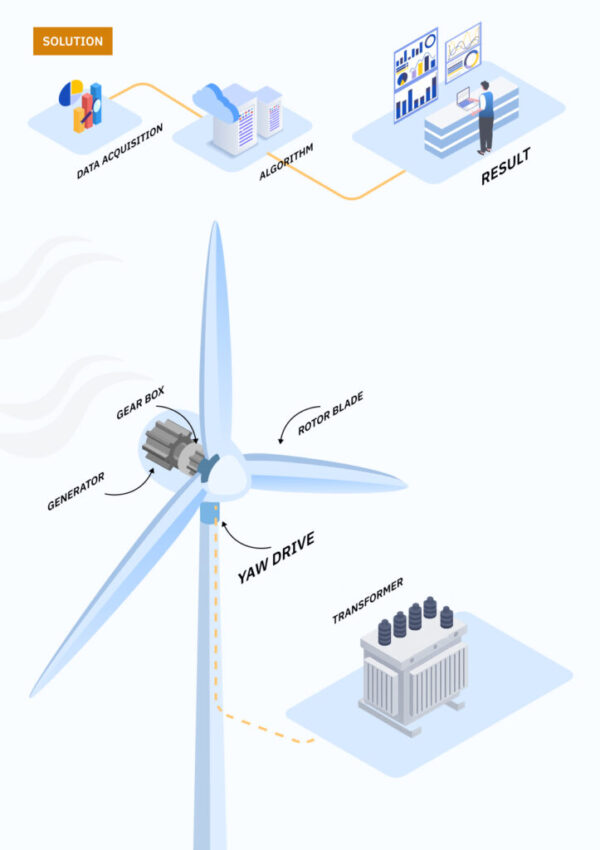

Diagnoses and pinpoints faults at the main electric and mechanic components of a Wind Turbine, including the Generator, Power Electronics, Gearbox, Pitch and Yaw Motors, and Transformer.

Key Principles and Technology

Comprehensive Turbine Component Monitoring

Continuous monitoring of key turbine components including the generator, power electronics, gearbox, pitch and yaw motors, and transformer.

Advanced Electrical Signature Analysis

Algorithms analyze electrical parameters to detect both electrical and mechanical degradations at an early stage.

Non-Intrusive Measurement Approach

Relies solely on electrical variable measurements, avoiding the need for vibration, temperature, or intrusive mechanical sensors.

Electric Park’s Vector & Harmonics Analysis

Detects abnormalities related to imbalance, harmonics, and dynamic load variations within turbine systems.

Real-Time Data Acquisition & Processing

Captures fast-changing turbine operating conditions during variable wind speeds.

Scalable Wind Farm Architecture

Suitable for individual turbines as well as large, multi-turbine wind farms.

Benefits & Implementation

Benefits

- Immediate Action Through Live Monitoring

- Early Fault Detection Across Electrical & Mechanical Assets

- Improved Energy Efficiency & Power Output

- Reduced Maintenance & Downtime

- Lower Operational Costs

- Enhanced Turbine Reliability & Asset Life

Implementation

- Deployment of Electrical Measurement Devices

- Rapid Commissioning & Baseline Establishment

- Continuous Remote Data Transmission

- Advanced Fault Detection & Diagnostics

- Real-Time Dashboards & Automated Alerts

- Integration with SCADA & Wind Farm Control Systems